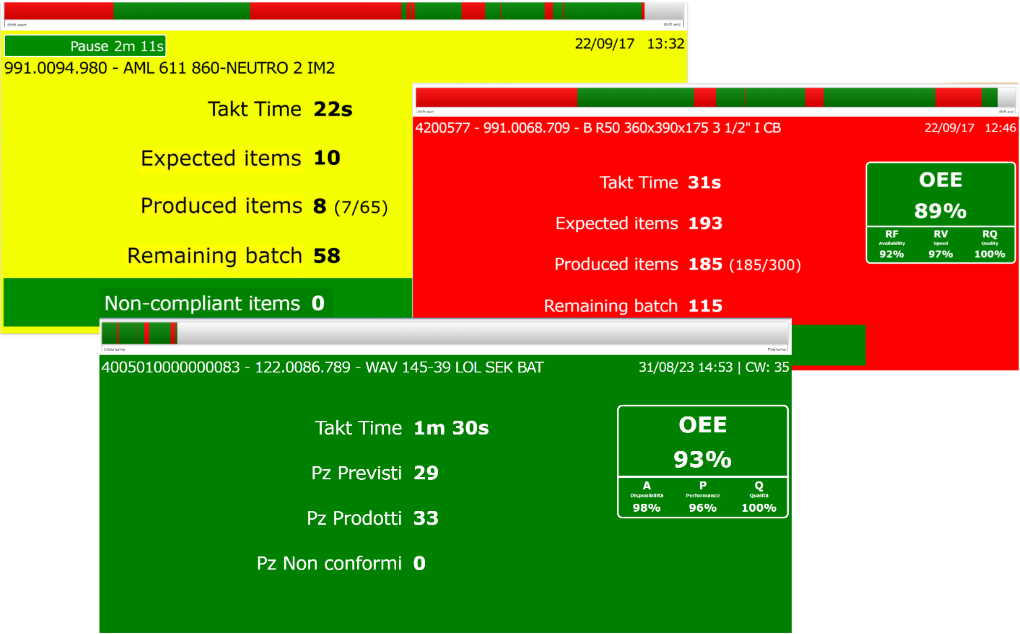

Production Data

The Andon boards display the main production data.

The different background colors provide an immediate perception of the production progress, as they are associated with different OEE percentage ranges..

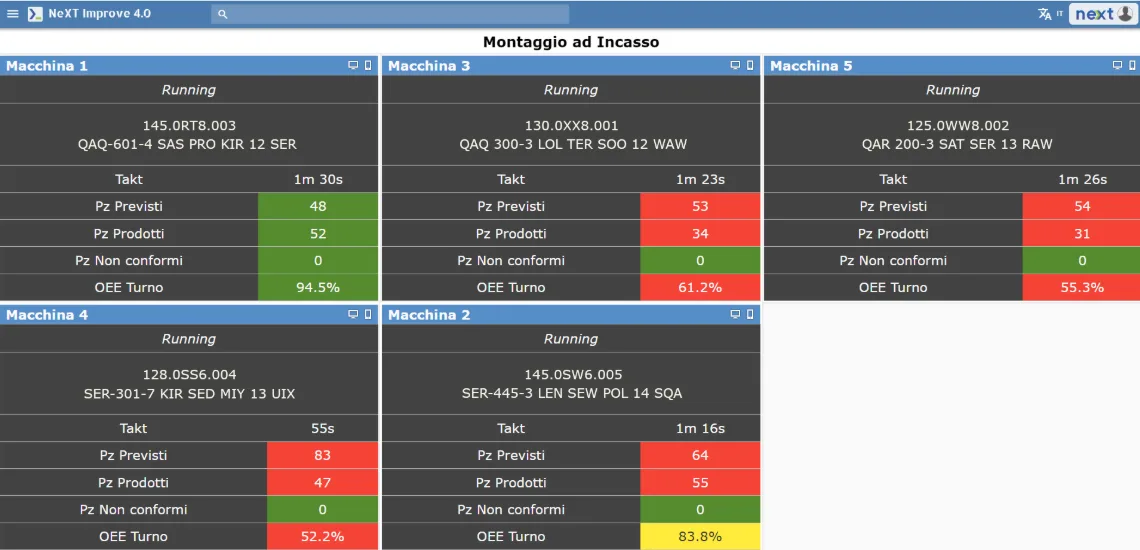

Aggregated Data

The information flows into different dashboards,, dedicated to different roles and tasks.

One dashboard is dedicated to showing aggregated data regarding all the lines, providing an overview of the department. It is then possible to drill down into the details of each individual line.