The logic of the system: actions suggested by the Smart Agent

Achieved results

The system, thanks to the logic of reinforcement learning, progressively improves starting from the knowledge base built by experts.

This knowledge transfer has made the system, in a very short time, autonomous and almost infallible.

These results have finally culminated in a scientific publication titled “A decision theory approach to support action plans in cooker hoods manufacturing”

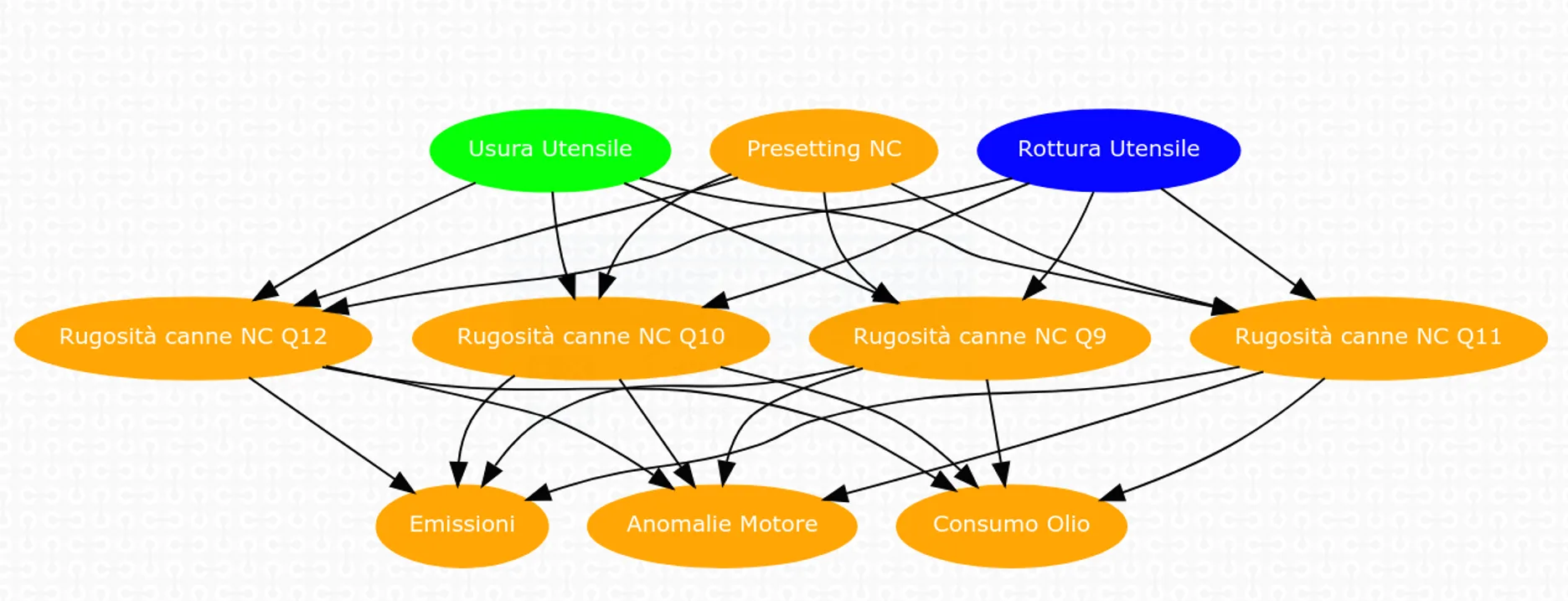

Implementation of the Bayesian Network for the Probabilistic Management of Quality Issues

The first step in implementing an A.I.O.C.A.P. system is to create a probabilistic knowledge base.

This base, organized into a Bayesianan Network, allows the system to propose solutions in the form of an action plan.

The Bayesian network calculates the degree of probabilistic belief about the current state of the process, following events related to quality issues automatically detected by the system.

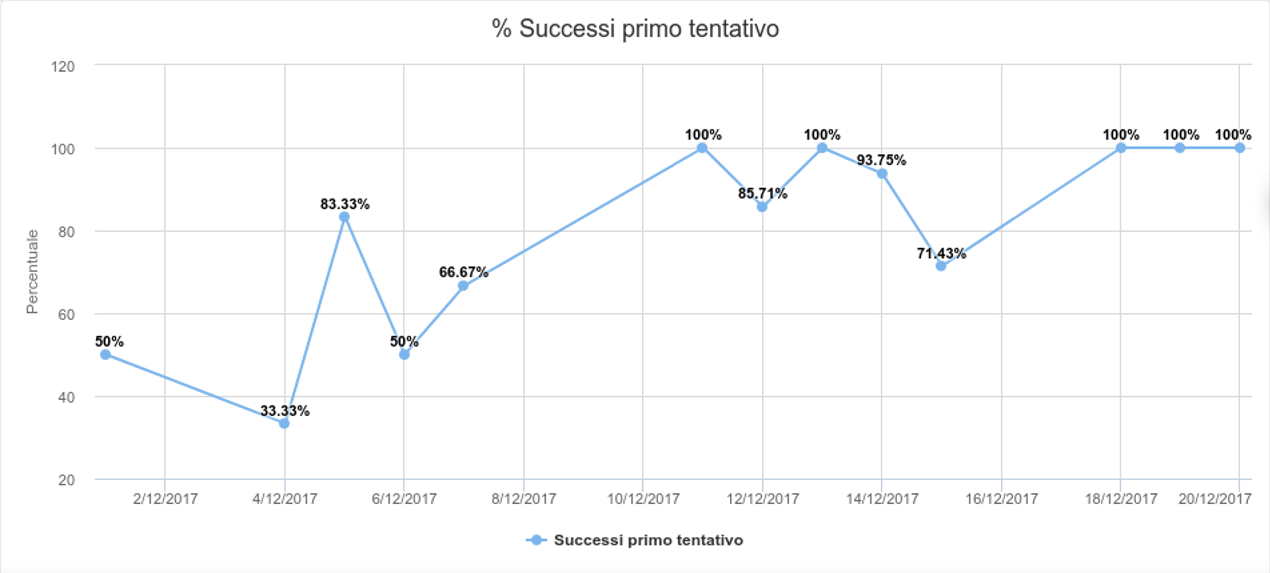

Learning curve

The graphs related to the use at a client’s facility highlight how, after about a year of learning, the system achieved an average of 95% succes on the first attempt.

In the initial phase, the graph shows a learning trend, although with some fluctuations. However, in just a few months, the system achieves excellent results.

The added value of the system is confirmed by the support it provides to new operators, who are not experts in the production process. The system transfers the knowledge learned from experienced operators, thus optimizing learning and performance.

Optimization of Production Processes: A Case Study in the Kitchen Hood Sector

The project led to a case study, which was the basis for a scientific publication that won the “Second Best Paper” award from the University of Cartagena, under the theme “Manufacturing and Industrial Process Design.” The title of the paper is “A decision theory approach to support action plans in cooker hoods manufacturing.