What and how: the smartest way to improve

Detailed reports and graphs for statistical control

The results obtained from the analysis phase are presented in a series of comprehensive reports, with data organized in both tabular and visual formats. These reports are derived directly from the statistical process control, offering a clear and in-depth overview of performance.

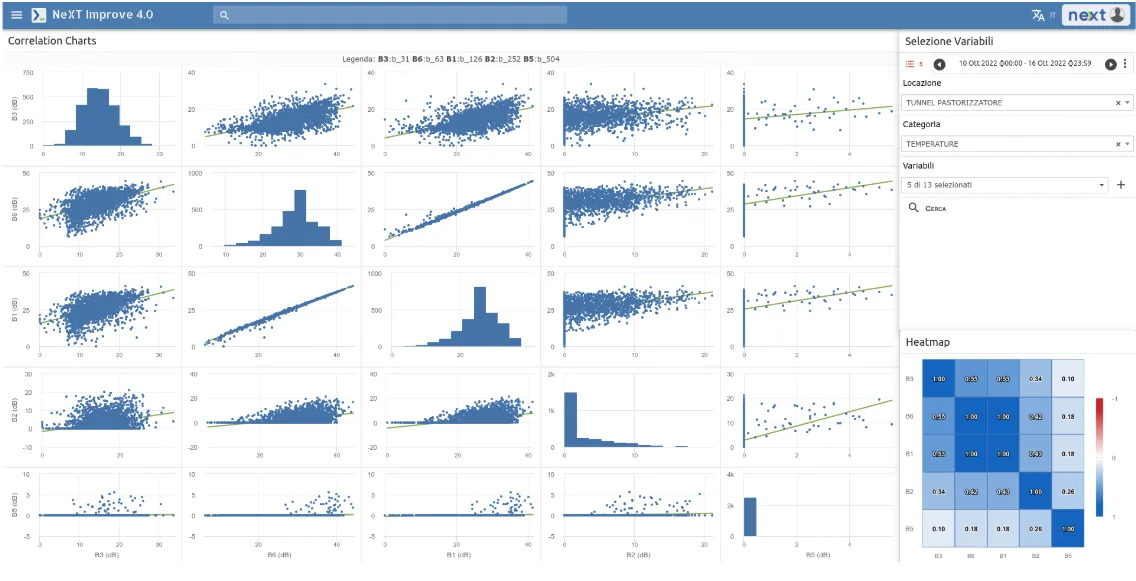

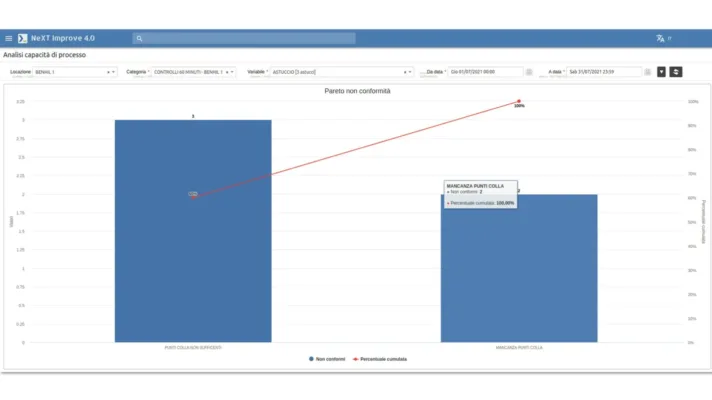

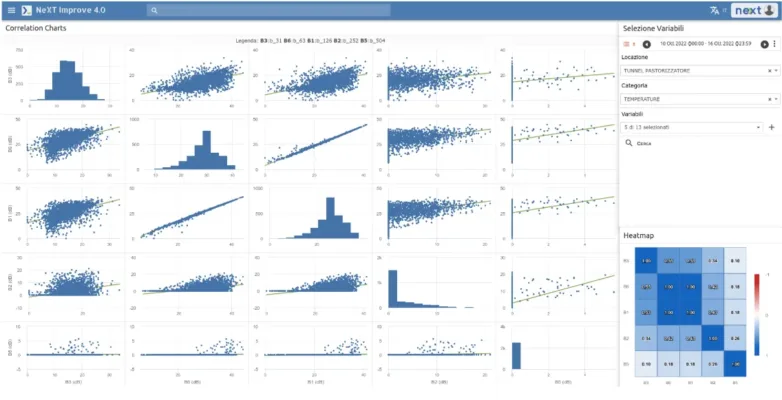

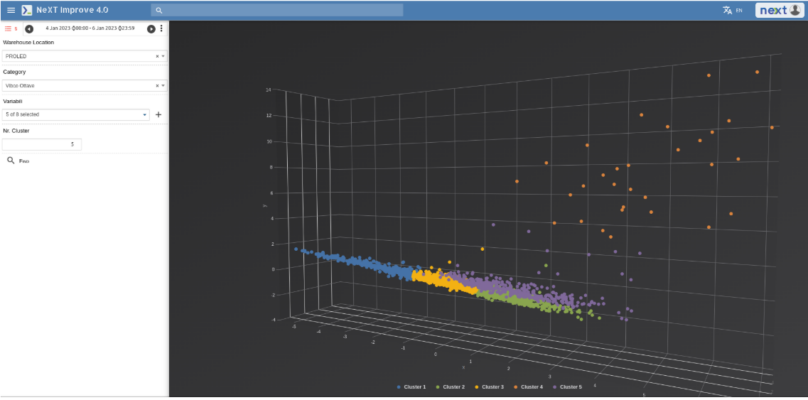

The graphs used in the reports are of various types, including: frequency histograms, Gaussian distribution analysis, Pareto charts, process capability, and multivariate analysis. The latter allows for the examination of correlations between variables to optimize and improve the process as a whole.