From the traditional production cycle to the Just-In-Time system

Typically, production is seen as a flow that goes from upstream to downstream, from the initial islands to the final assemblies.

Kanban reverses the point of view: the production process is conceived as an operation that goes from downstream to upstream.

Kanban is a tool of Just-in-time system used for restocking process phases, only when there is a real need.

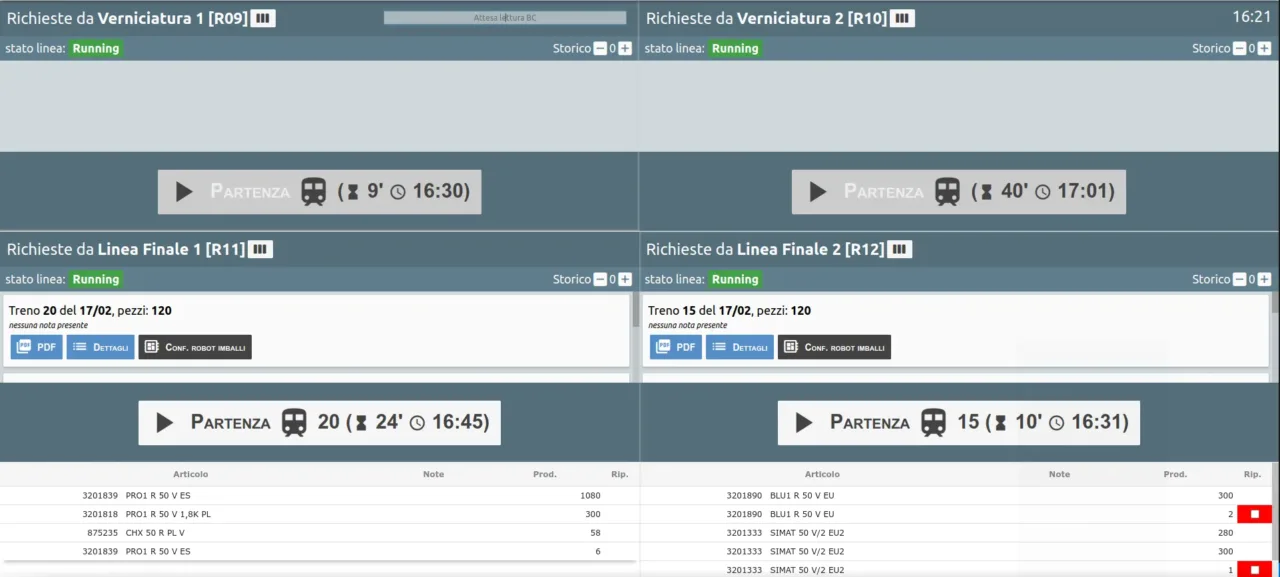

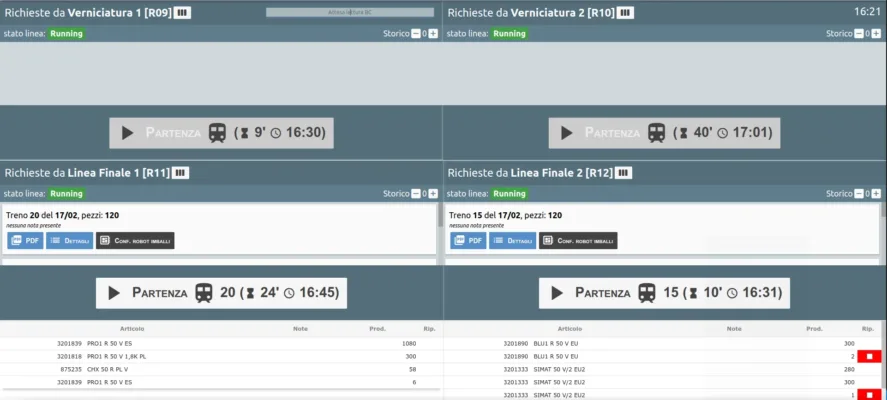

Digital Kanban

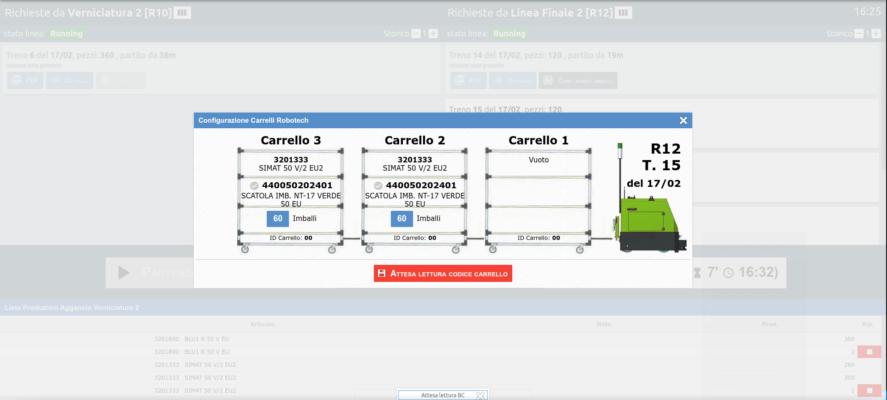

Through a dedicated interface, the operator can manage schedules: plan or reschedule an activity.

The system pulls information directly from the ERP.

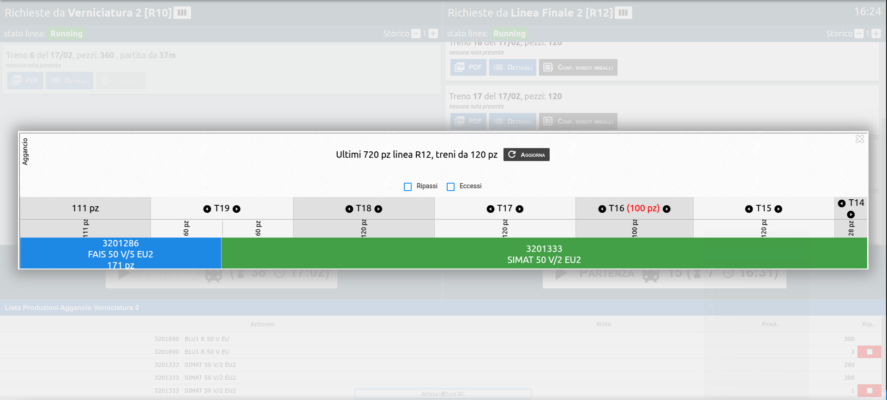

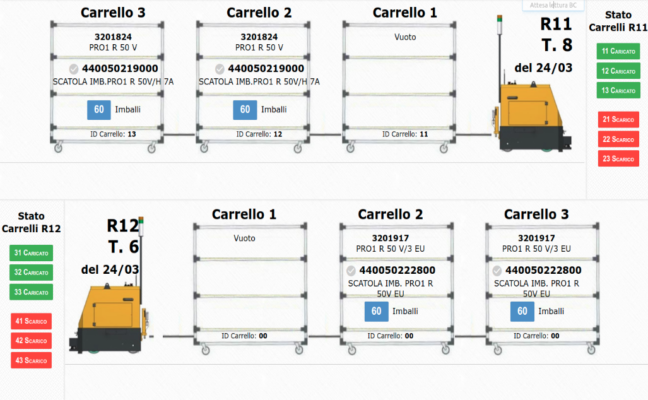

Inventory planning

"Each schedule adds a small block to the list: the green block represents the one currently in production. The 'Change model' button activates a new schedule.

It is possible to manage multiple routes and therefore different inventory trains.