Advantages

The benefits of using a tool like the EEM are quite clear:

- Simplification of maintenance activities: the mean time to repair (MTTR) and the scheduled maintenance time are reduced;

- Improve of the plant's reliability;

- Exploitation of company know-how through the involvement of teams with specific skills;

- Reductionof operational costs throughout the asset's lifecycle (LCC)

Skills

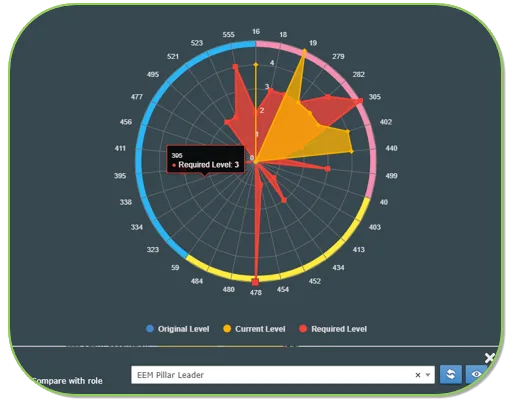

The skills are divided into three categories:

- Reactive

- Preventive

- Proactive

Each role requires a level of competence (from 0 to 5) in specific skills: the radar chart visually highlights this relationship.

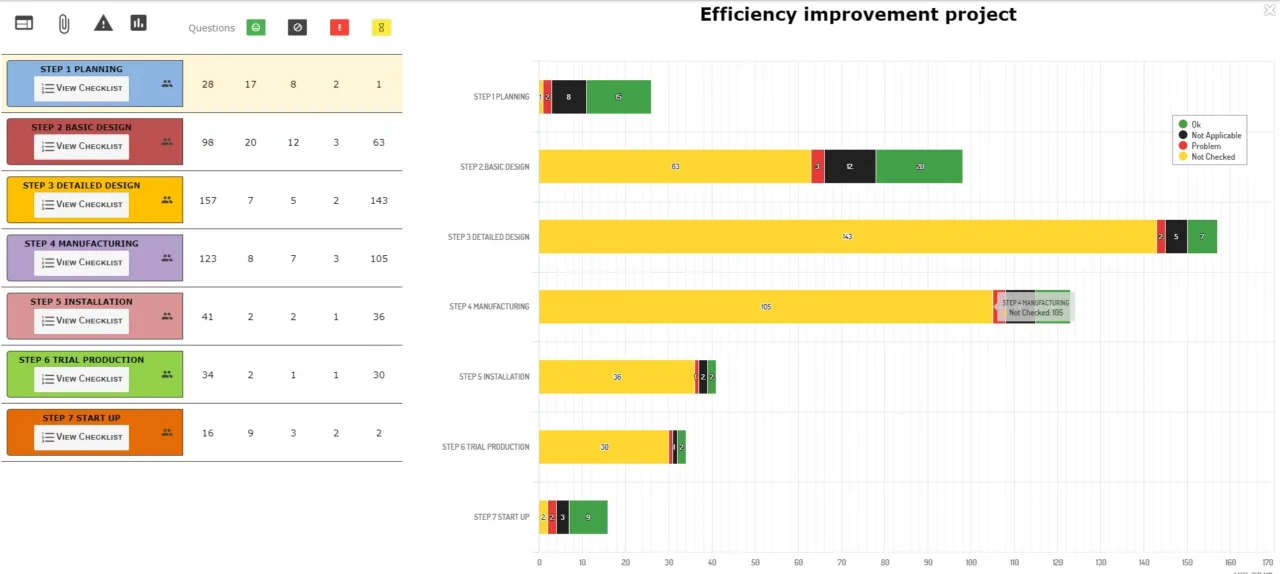

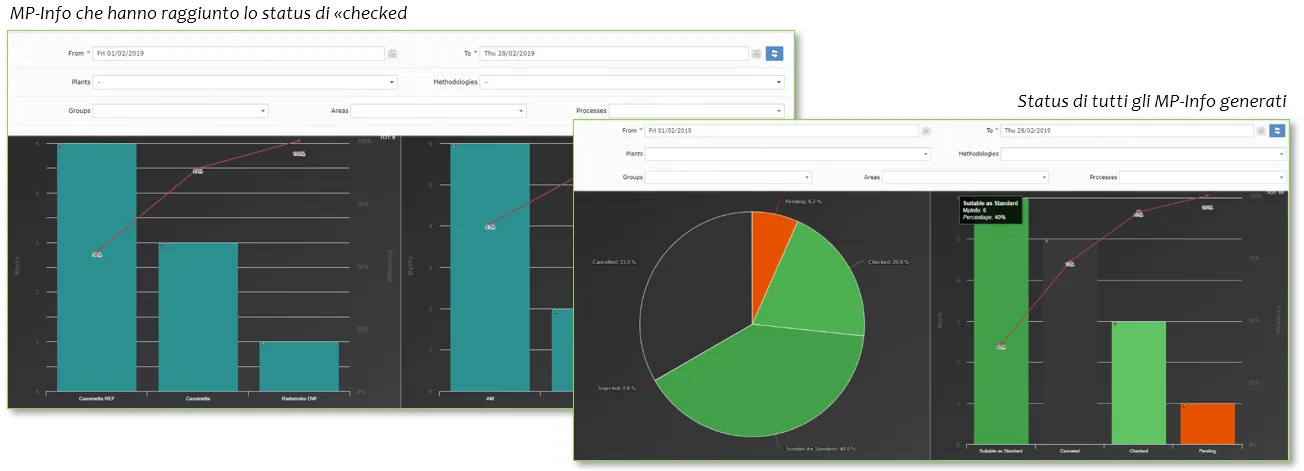

Reports

The reports, strictly visual, allow for an immediate perception of how many checklists and MP info have reached the "checked" status.

The data can be filtered by date, plant, processes, etc.

Project model repository

Each project is accompanied by thematic folders in which relevant documents can be uploaded (es. LCC, Machine Ledger, FMEA, ecc..)

Every time a new project is created, it will carry the folder structure described in the "Project model repository."