Beyond reactive maintenance, the occurrence of a breakdown is already a sign of ineffective maintenance management. Our goal is to 'eliminate' these types of interventions

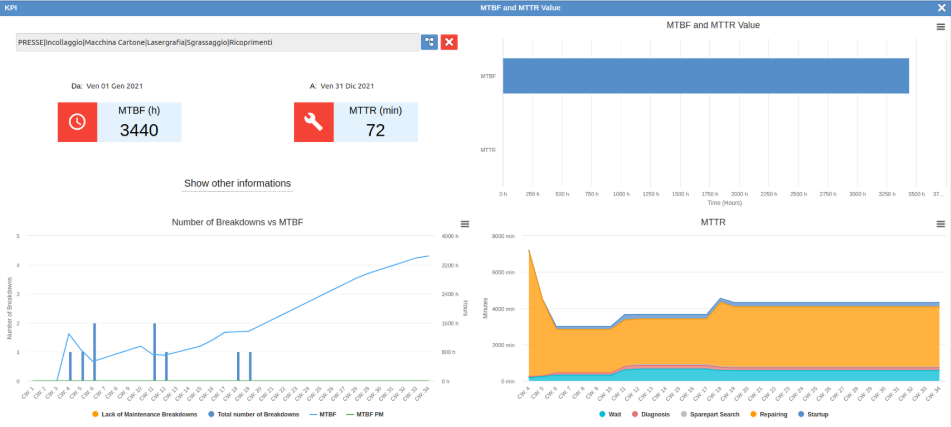

Acquisition and analysis of KPIs

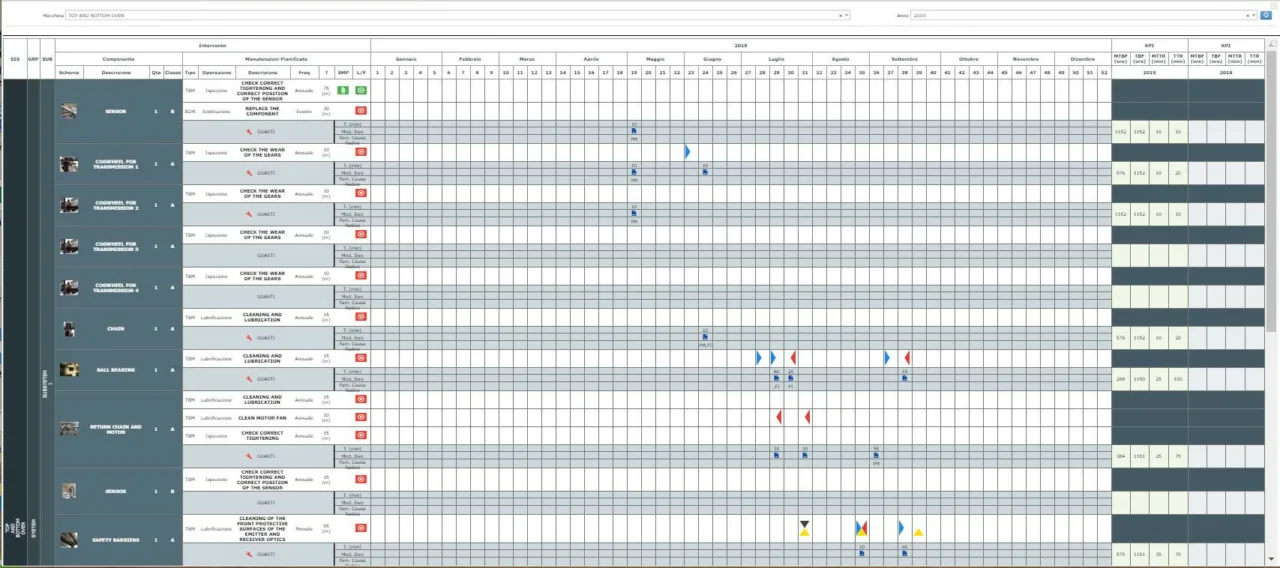

Machine Ledger s a large data collector, through which every intervention, whether scheduled or unexpected, the time dedicated to the activity, and the solutions adopted are recorded: all with one goal in mind, continuous improvement, zero waste.

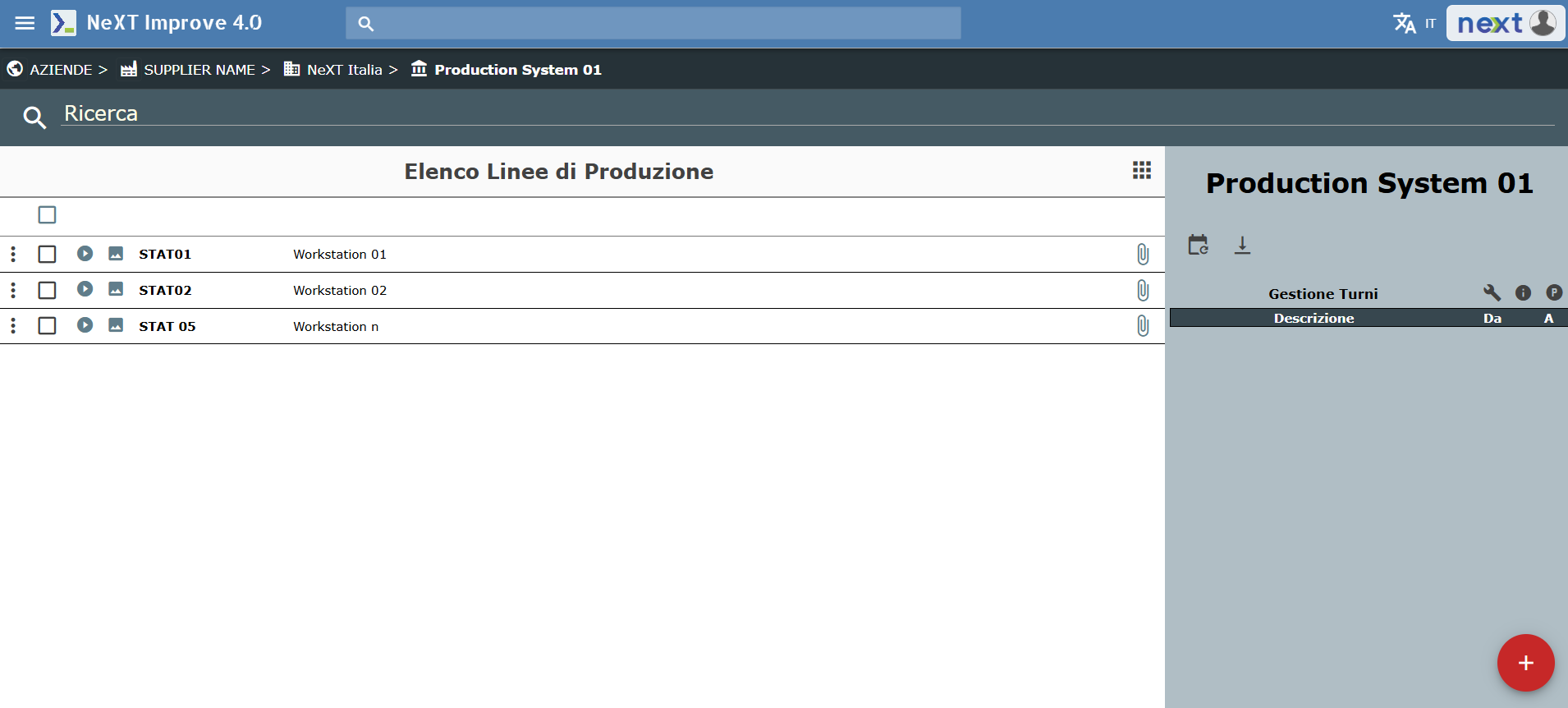

A Cloud platform to connect effectively with the machine supplier

The platform is accessible by both thecustomer and machine supplier, in order to optimize maintenance management.

The supplier will easily configure the machine and each individual component.

The customer will simply need to import what has been configured by the supplier (BOM of the machine and Machine Ledger).

HBM e CBM Maintenance

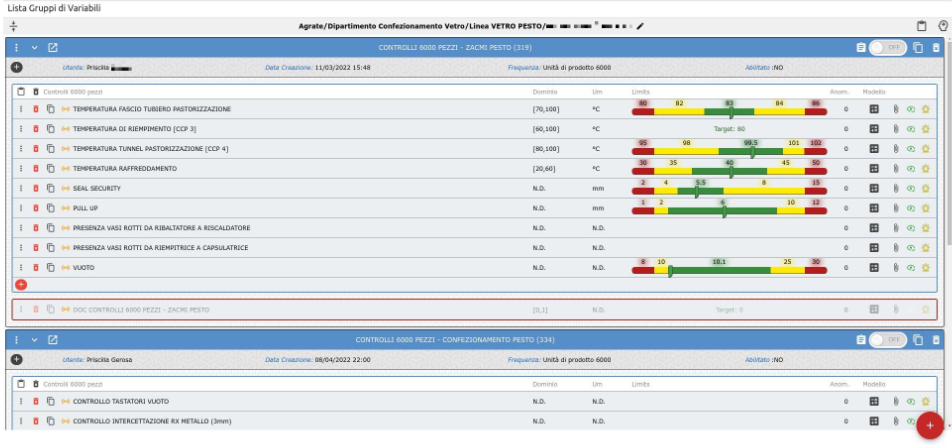

The configuration of process variables involves defining limits, thresholds, or cycles.

Exceeding these values triggers an automatic scheduling of maintenance directly in the Machine Ledger Calendar.

This way, the maintenance of a component will only occur when strictly necessary, minimizing the waste of time and still usable materials.

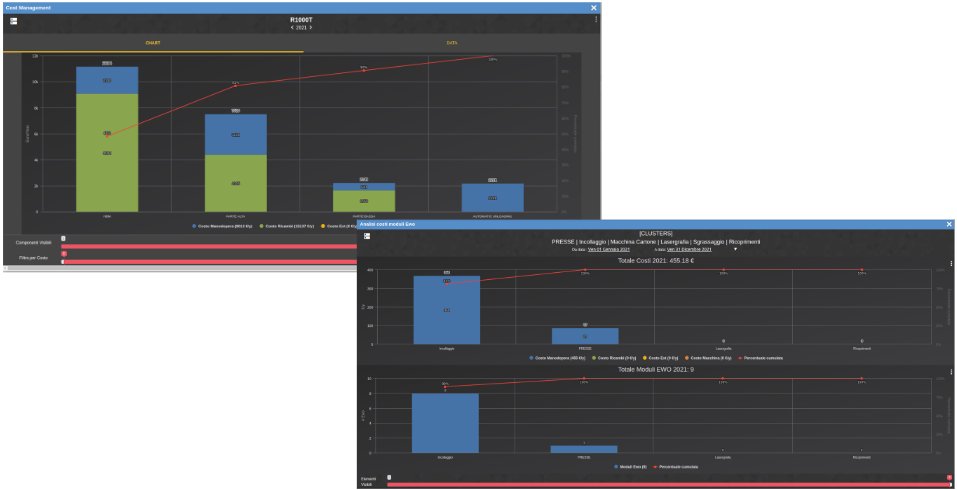

Valuation of maintenance costs

By the Machine Ledger, it is possible to evaluate both the cost of preventive maintenance and that of reactive maintenance.

Gestire le manutenzioni non è stato mai così semplice ed efficace

Avvia il processo di digitalizzazione della gestione delle manutenzioni.

Rendi anche le manutenzioni in linea con i paradigmi Industria 4.0.

Pensa in grande.

Pensa NeXT.