Quality Officer

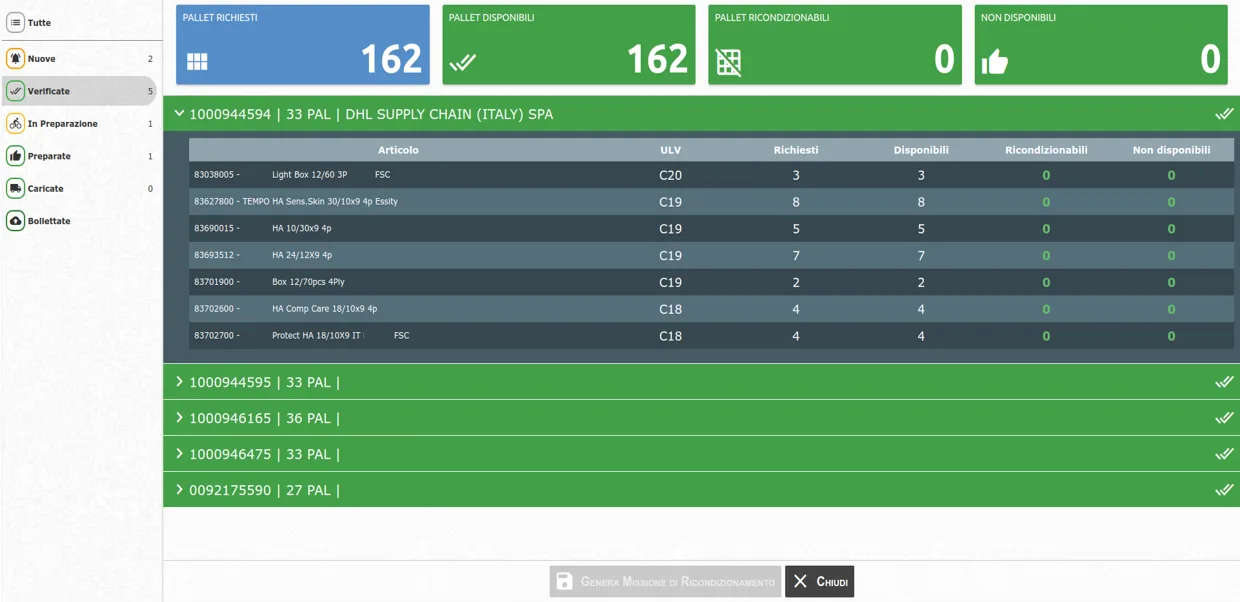

The module reserved for the shipping department is responsible for:

- Blocking/unblocking goods and locations

Warehouse Key User

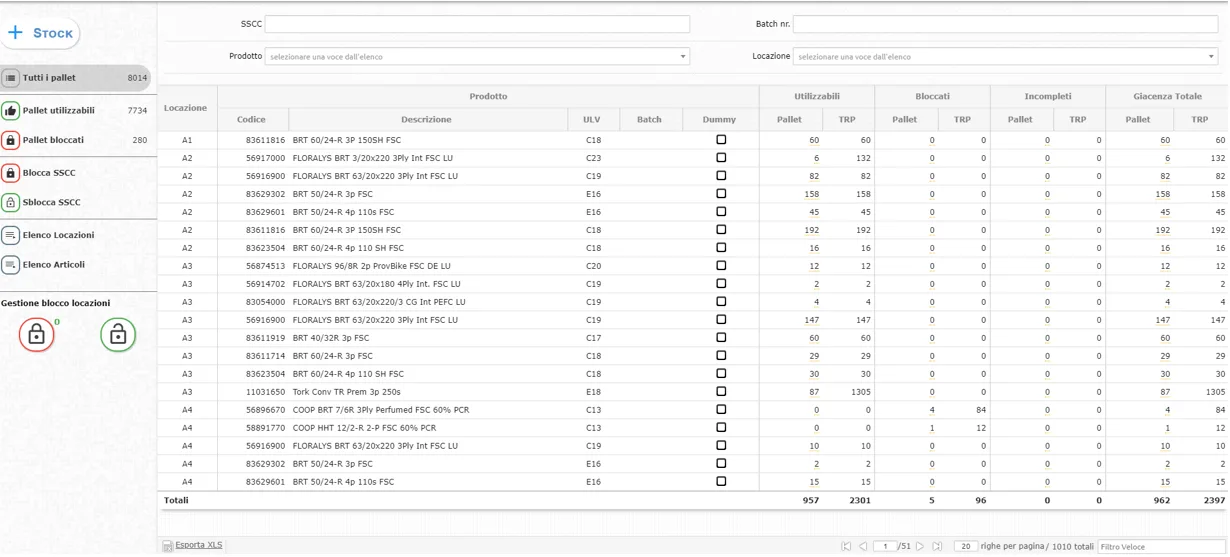

The module reserved for the shipping department is responsible for:

- Warehouse stock

- Warehouse movement log

Warehouse forklift operator

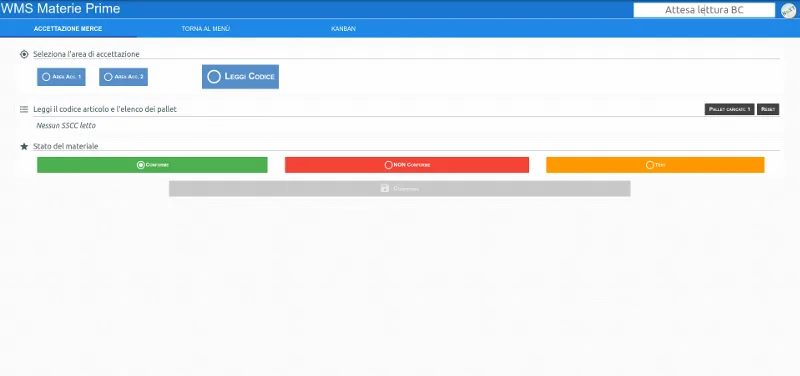

The module reserved for the warehouse forklift operator is responsible for:

- Receiving incoming goods

- Transferring goods between locations

- Reprinting pallet labels