Vuoi ricevere un invito gratuito per visitare la fiera MECSPE di Bologna, dal 4 al 6 marzo ?

Compila il form e saremo lieti di inviarti un invito per l’accesso gratuito… e vieni a trovarci al Padiglione 21, stand B37

Soluzioni IA per il miglioramento delle performance produttive

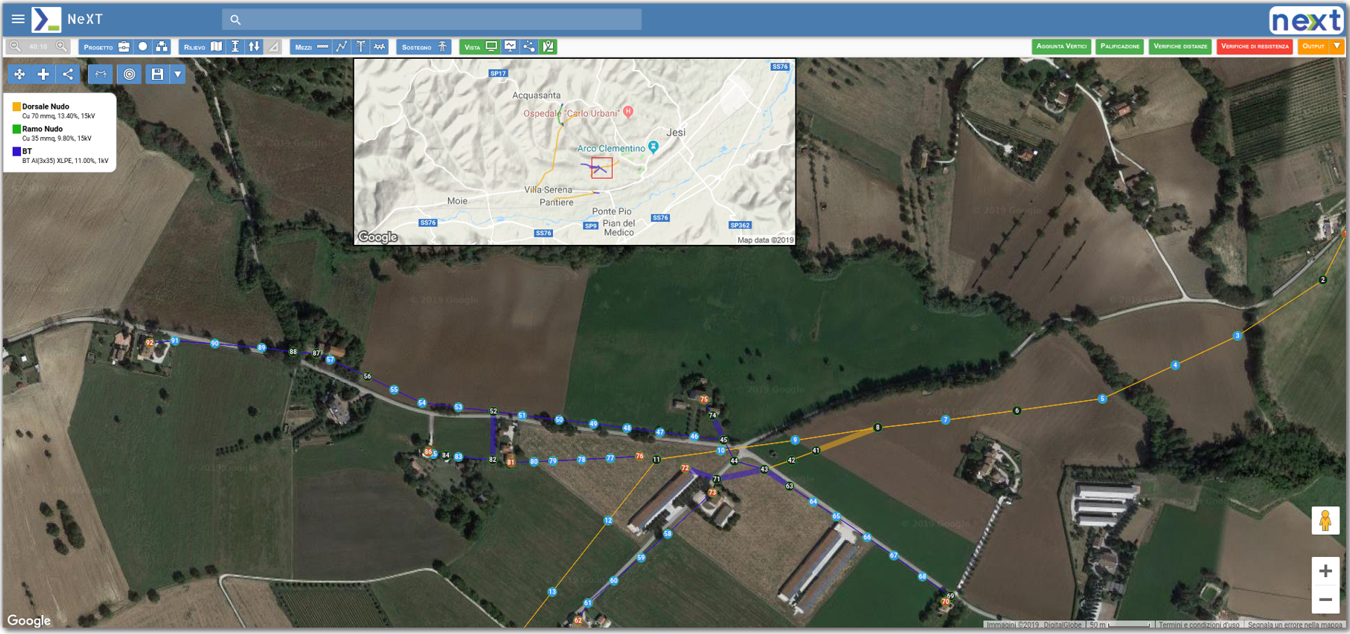

Next vuole rappresentare, per qualsiasi realtà industriale, un vettore di digitalizzazione.

La digitalizzazione di tutti i processi aziendali, soprattutto quelli legati al settore manifatturiero, può essere la chiave per vincere la sfida più importante, specie per le generazioni future.

Digitalizzare consente anche di creare un flusso agile e continuo di comunicazione e condivisione.

E facendo questo, Next, vuole anche ritagliarsi un ruolo sempre più significativo nella costruzione di un mondo sostenibile, più green.

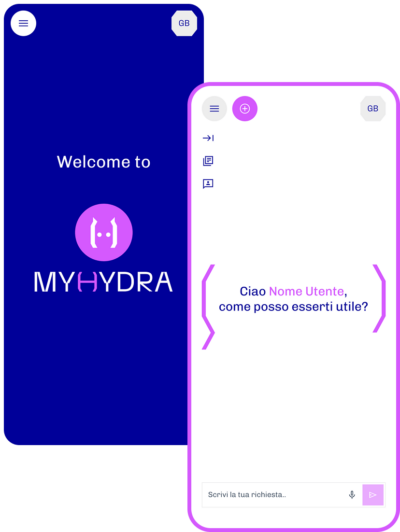

MyHydra nasce con l’obiettivo di modellare identità digitali capaci di prendere decisioni proattive, adattandosi al contesto e interagendo in modo naturale con gli utenti.

Improve

La digitalizzazione che integra intelligenza e innovazione in ogni fase dei processi produttivi

Next to Goals

Next in “numeri“: raccontano un percorso e disegnano traiettorie che puntano sempre “un po’ più là“.