Would you like to receive a free invitation to visit the MECSPE fair in Bologna, from March 4th to 6th?

Fill out the form and we’ll be happy to send you an invitation for free access… and come visit us at Pavilion 21, stand B37

AI solutions for improving production performance

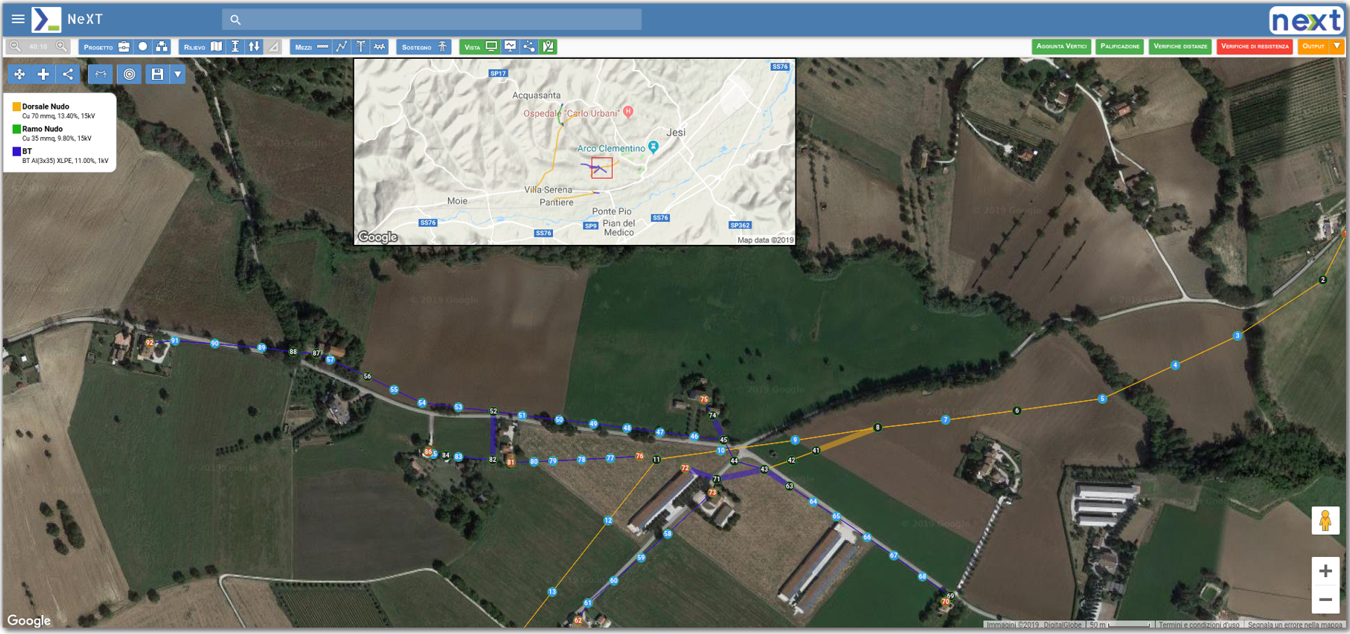

Next aims to represent a vector of digitalization for any industrial reality.

The digitalization of all business processes, especially those related to the manufacturing sector, can be the key to overcoming the most important challenge, particularly for future generations.

Digitalizing also enables the creation of an agile and continuous flow of communication and sharing.

By doing this, Next also aims to carve out an increasingly significant role in building a sustainable, greener world.

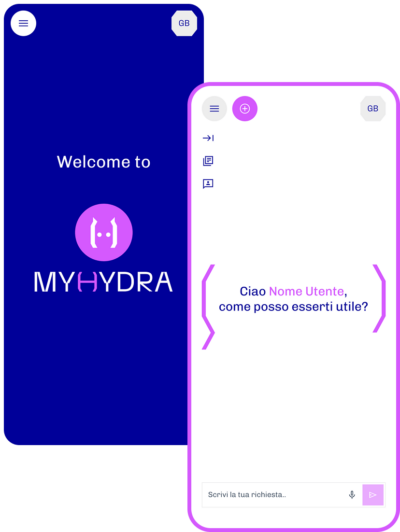

MyHydra was created with the goal of modeling digital identities capable of making proactive decisions, adapting to the context, and interacting naturally with users.

Improve

Digitalization that integrates intelligence and innovation into every phase of the production processes.

Next to Goals

Next in “numbers”: they tell a journey and map out paths that always reach a little further.