L’IA a supporto dei processi di Digitalizzazione e Monitoraggio dei processi produttivi

Il focus di IMPROVE è sempre stato il value stream: dalla commessa alla spedizione, con l’obiettivo di eliminare tutto ciò che costituisce spreco.

Alla base di tutto ci sono i dati.

I dati hanno sempre alimentato gli strumenti utili alla fase di improvement, dove si costruisce la competitività.

Ora, con l’integrazione di MyHydra, il framework si arricchisce di un livello di intelligenza artificiale capace di analizzare, comprendere e agire sui dati in tempo reale, trasformandoli in insight immediatamente utili per decisioni operative e strategiche.

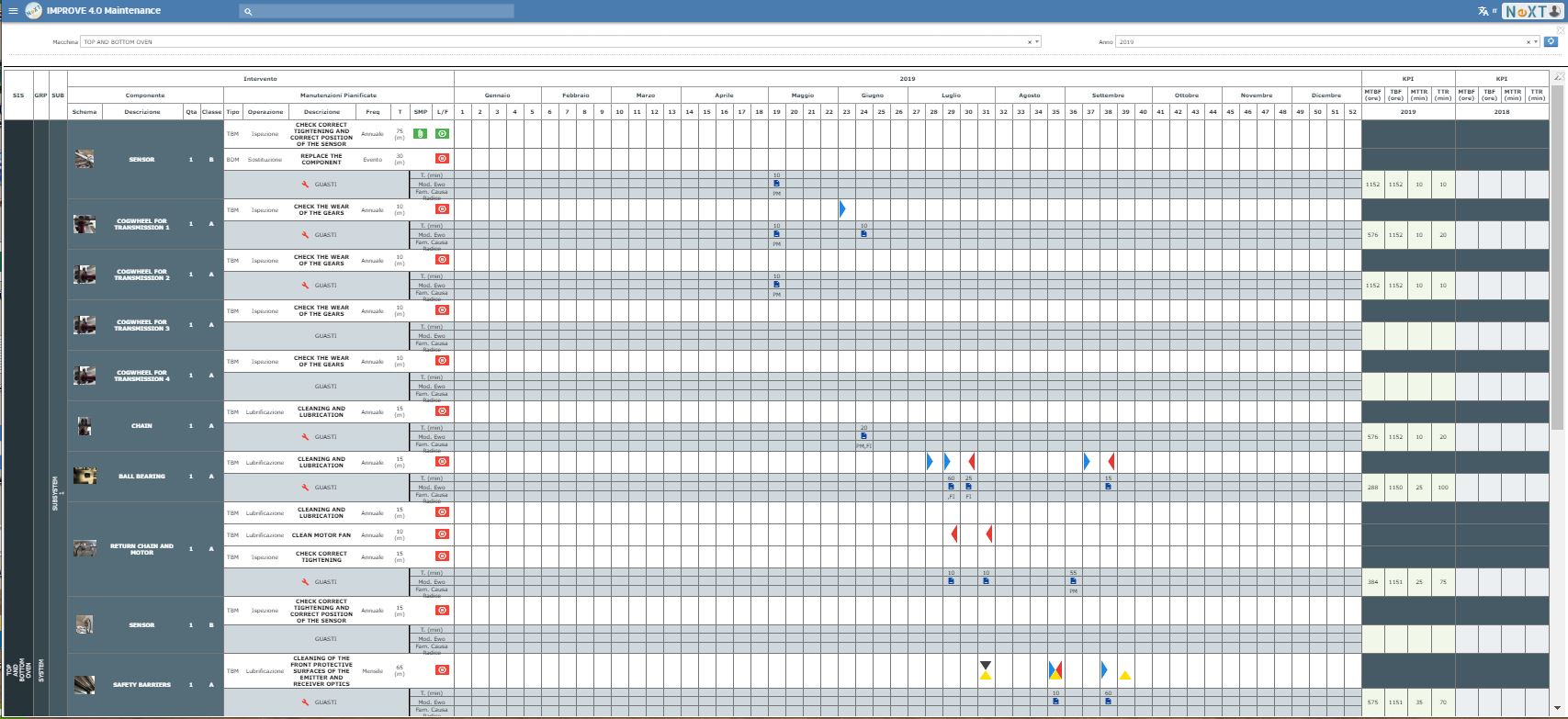

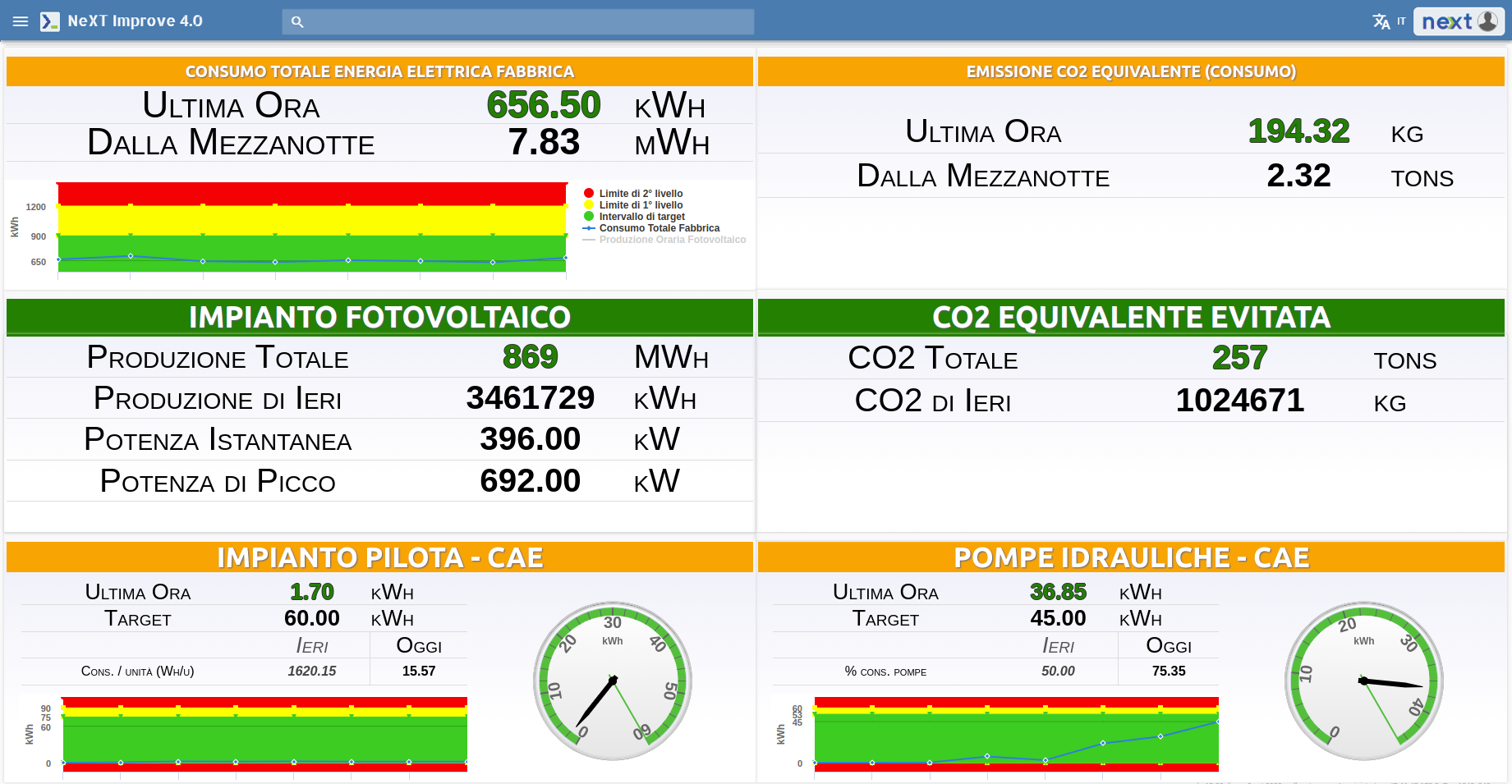

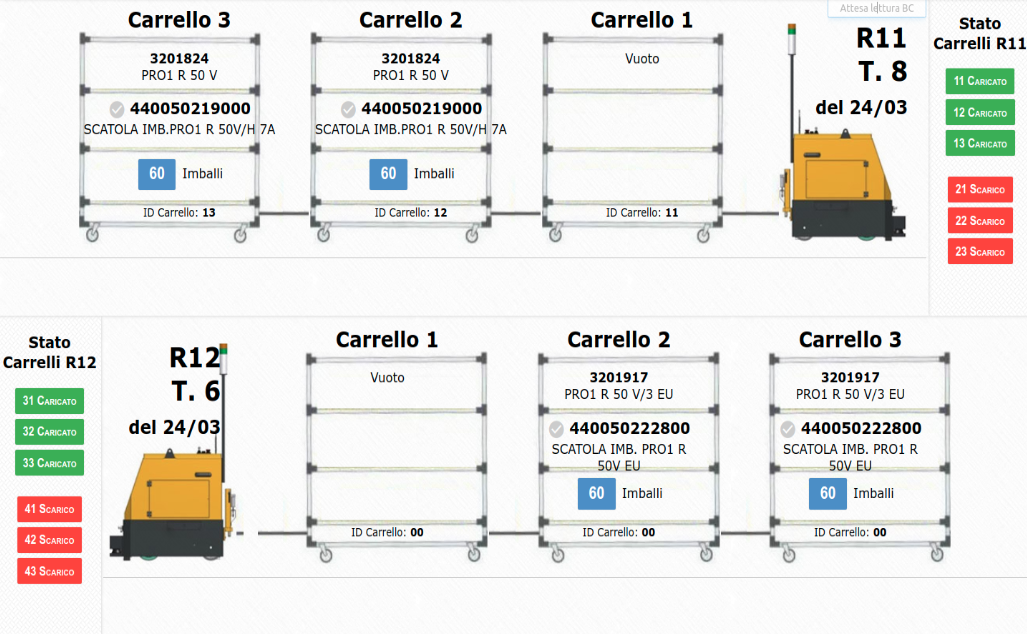

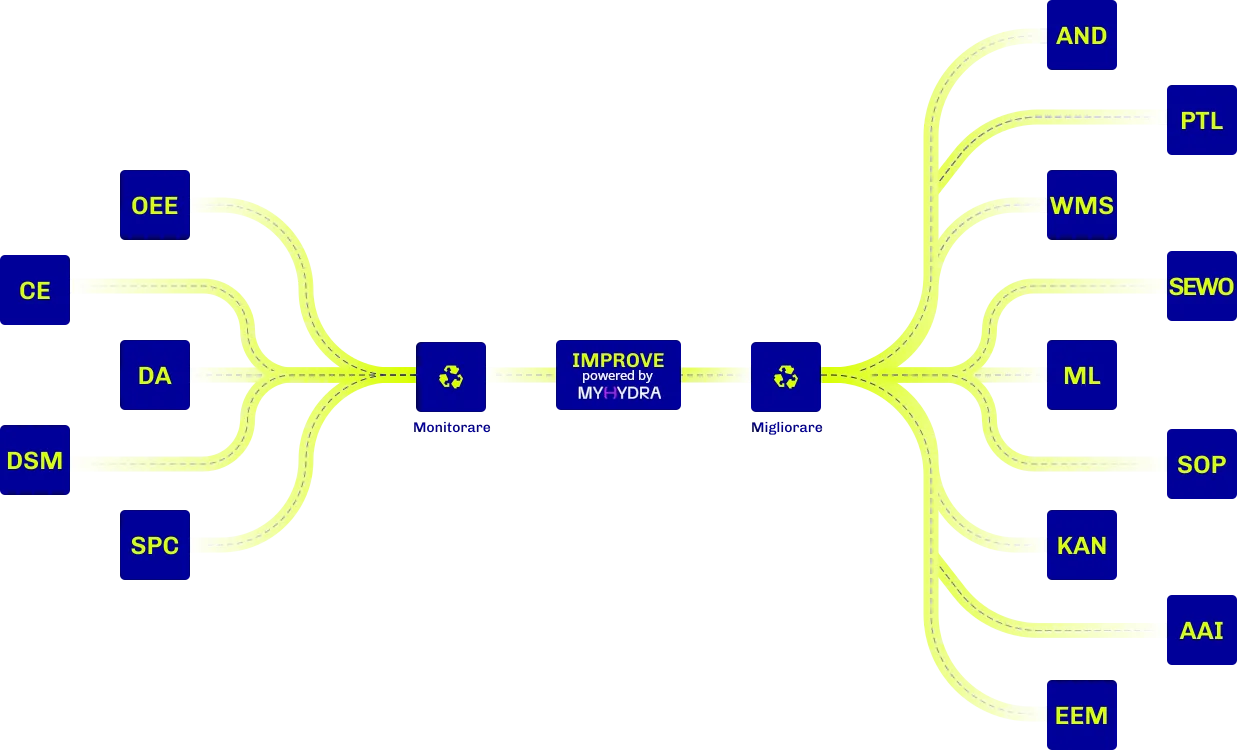

Soluzioni per monitorare

Il miglioramento inizia sempre dalla conoscenza profonda dei propri processi, dei punti di forza e, soprattutto, dei punti di debolezza, perché è laddove si nasconde lo spreco che si genera il margine di miglioramento delle vostre performance.

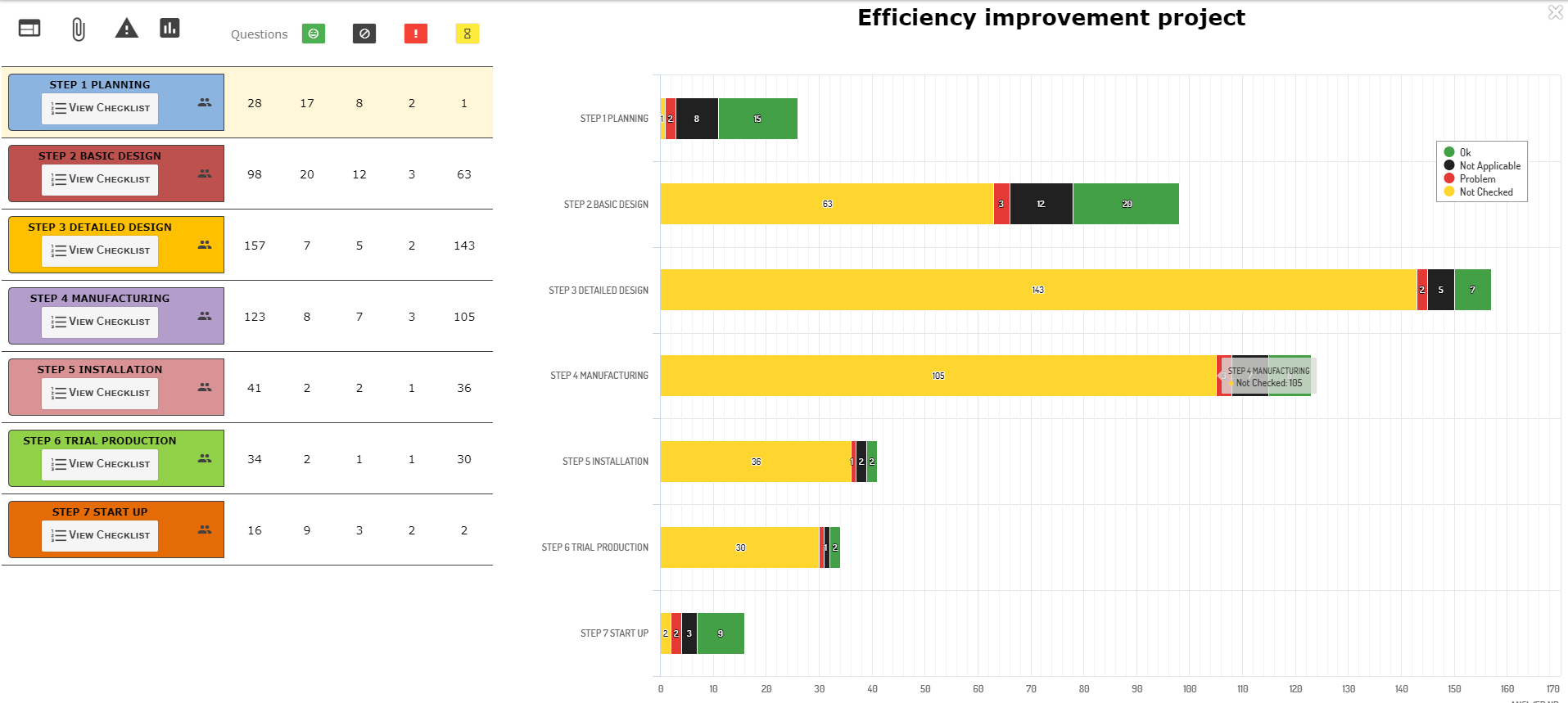

Soluzioni per migliorare

Entrare in possesso dei dati che ci forniscono una fedele fotografia dello stato delle cose, non è sufficiente.

Occorre anche agire, utilizzando gli strumenti idonei per il miglioramento continuo.