Efficiency monitoring:

OEE & Andon

OEE (Overall Equipment Effectiveness) and Andon: they work in perfect synergy.

first to allow a detailed and in-depth analysis of production, in the short and

medium term; the second to highlight the production trend, real time.

The KPIs of efficiency:

availability, performance, quality

Monitor downtime and causes.

Monitor the speed of the production flow.

Monitor scraps and causes.

The state of things

We provide the image of the actual production situation

The waste

We identify the causes of waste

Where to intervene

We identify where waste occurs most often

Decision-making tool

We provide a valuable support tool for decision makers

Ready to… do better?

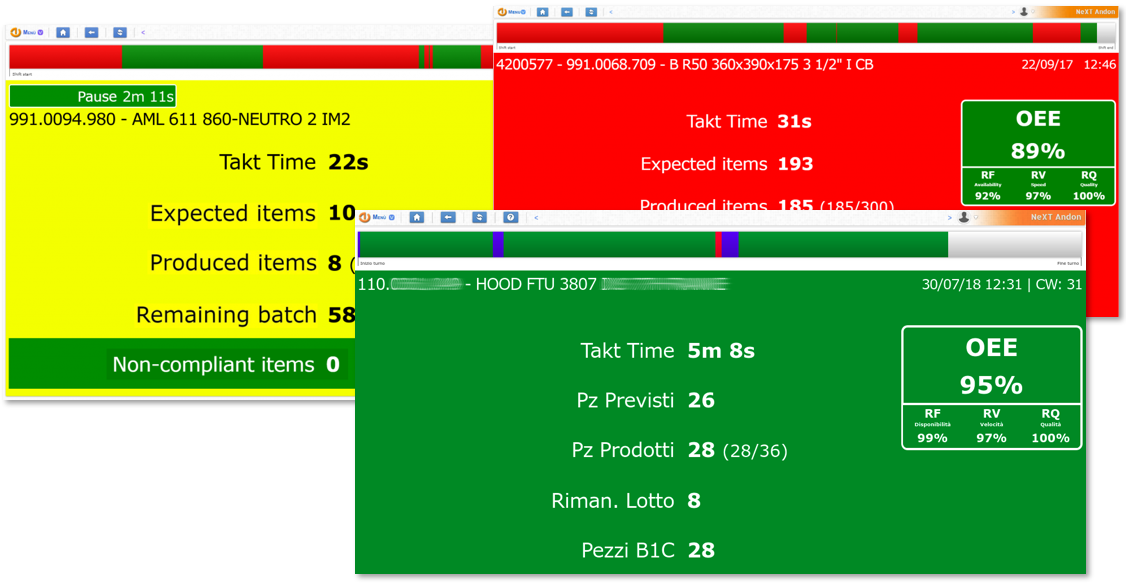

Acquisition of real time KPIs: Andon

The data, in real time, are taken directly in the field, through::

- A touch device

- Sensors

- PLC

The touch panel also serves to explain stoppages, micro-stops, slowdowns and quality problems.

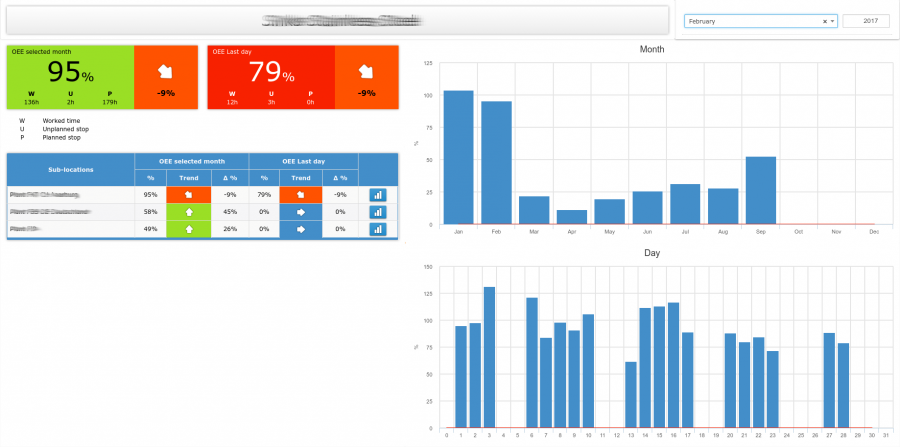

Data analysis in the short and medium term: the OEE

The key questions a manager wants to answer are:

- “How am I performing when I work?“

- “How many compliant products are produced during the real production time?“

Know how many times the machine stops and why; how many slowdowns occur and why; how many products need to be reworked because they are defective and why … all these questions can be answered!

Your data everywhere: mobile first

The interfaces are designed to be immediately understandable and portable.

They adapt to any device: monitors, tablets and smartphones.

The OEE overview: a worldwide system

Why limit yourself to knowing the efficiency of a production line or a plant?

IMPROVE 4.0 by NeXT can connect all plants in the world, compare them and control them wherever you are …

Think big.

Think NeXT.

"Good enough is never good enough when the goal is excellence."

Ready to… do better?

© 2023 NeXT Srl Unipersonale - P.IVa. 02510420421 - Privacy and cookie information - Powered by Fuel31