Robot & AGV Movimentation

MPROVE is able both to extrapolate data from the System (OEE, Andon, SPC, process traceability, etc.) and to send information. Now we will talk about automation and robotics, how our software interfaces with the robots present in the plant, taking care of their routes through the sending of precise missions.

There are no specific types of missions that IMPROVE is able to send to the machines. Let’s look at a couple of examples.

The case study FCA VM Motori of Cento:

robots and pick to light

In the FCA VM Motori plant in Cento, our IMPROVE system has the task of managing the AGVs (Automatic Guided Vehicles) so that they move materials from the loading buffers to the lines. Here the AGV stops to allow the operator to read the engine serial number through a barcode reader. After that, it will start to advance slowly again, in perfect synchrony with the pick-to-light system, as well managed by our IMPROVE system.

What happens in practice? IMPROVE knows from the bill of materials the list of components to be installed on the finishing motor. In relation to this list, the AGV is sent to a specific line. The speed of the AGV is managed by IMPROVE according to the shelves indicated by the pick to light system, always managed by IMPROVE. Finally, IMPROVE will also adjust the height where the motor has to be held in relation to the height of the human operator. The operator will then proceed to assemble the motor, perfectly supported by both the AGV and the pick to light system, which will dictate the timing of movement of the AGV.

The MTD case study

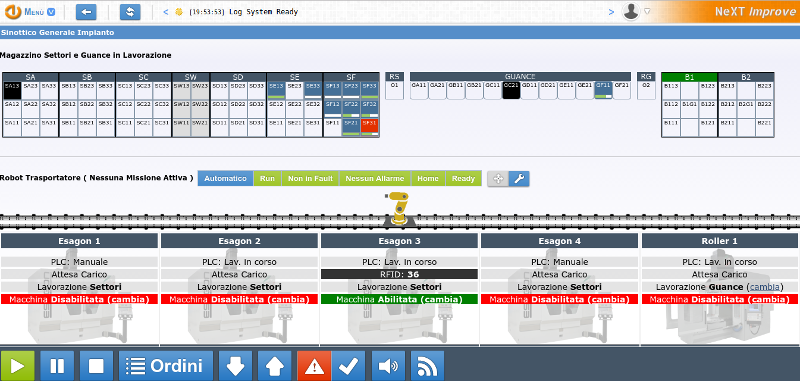

What has been implemented in partnership with CTF Automazioni for MTD is different. In this case, IMPROVE interfaces both with the PLC (which exchanges information with both the robot and IMPROVE) and with the CNC machines that process the parts.

Here the robot, having received the loading request from the operator, starts its rounds: it loads the part from the bay to the warehouse. It will then pick up the parts that need to be worked by the available machines. The machines will execute all the machining phases foreseen by IMPROVE on that piece (entered by the operator). Once the work has been completed, a signal will automatically activate the robot, which will pick up the piece and take it to the warehouse. From here, if all phases have been completed, it will be unloaded by the robot back into the bay, otherwise it will leave for other machines to complete all the working phases.

In the end, IMPROVE provides inputs to the robot so that it always knows what type of part has to be picked up and then automatically uses the different tools to take it and transport it.

"Any sufficiently advanced technology is indistinguishable from magic."

Ready to… automatize?

© 2023 NeXT Srl Unipersonale - P.IVa. 02510420421 - Privacy and cookie information - Powered by Fuel31