Kanban 4.0:

The digital solution for

Just-In-Time

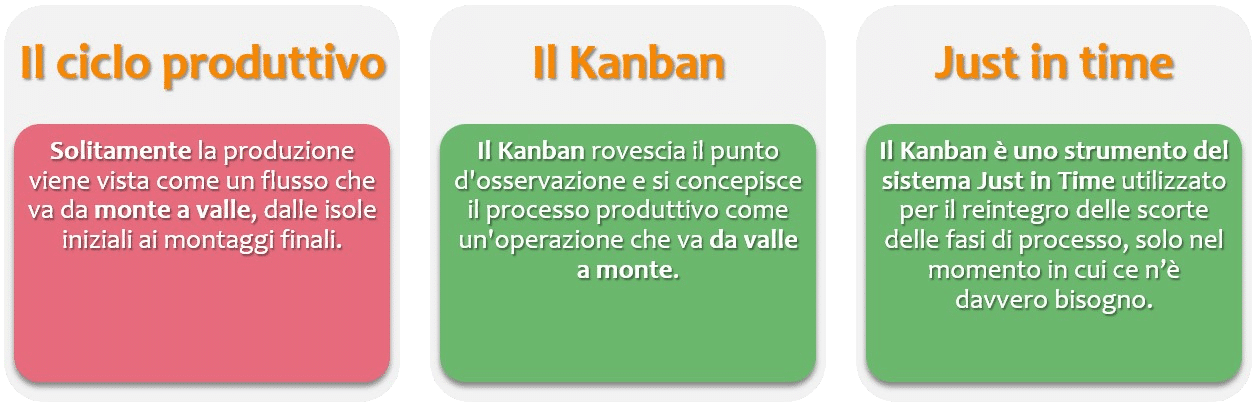

Kanban is a tool of the Just in Time system used to replenish the stocks of the process steps, only when there is a need.

This system allows real-time monitoring of the supply flow, avoiding the accumulation of resources in the warehouse, with all the costs, contingencies and errors that can result.

Kanban Objectives

The objective of the Kanban is simple. We could decline it in those three points:

Stock Reduction

Dead times elimination

Simplification of the procedures

Advantages of the Kanban

Warehouse Management

It noticeably reduces the stocks and improves the handling accuracy.

Data Management

It allows quick replies to the demand changes.

Production Management

It simplifies the scheduling of production

Ready to… save money?

Digital Kanban

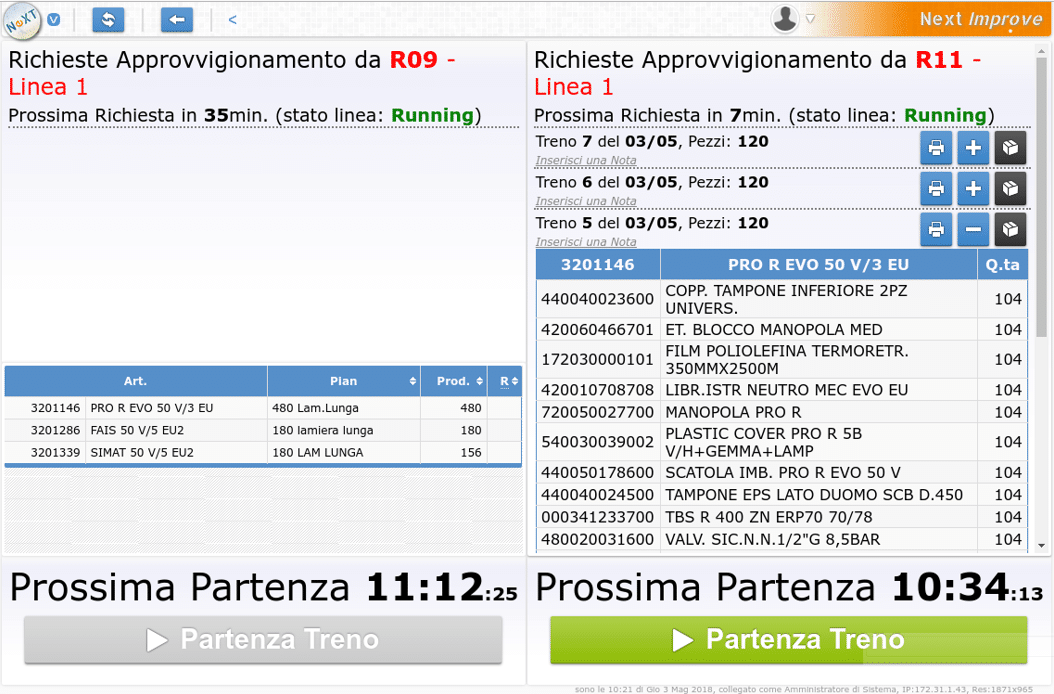

Through a special interface, the operator can manage the various schedules: planning or rescheduling an activity.

The system takes the information directly from the ERP.

Stock planning

Every planning adds a small block in the list: the block in green represents the one currently in production. The button “Change model” activates a new plan.

It is possible to manage more routes and therefore different trains of supplies.

Properly managing inventory replenishment means managing only what is necessary: it means eliminating waste

Think big.

Think NeXT.

“Time is a waste of money”

Ready to… save money?

© 2023 NeXT Srl Unipersonale - P.IVa. 02510420421 - Privacy and cookie information - Powered by Fuel31