It was 1913 when Henry Ford designed his first Ford T assembly line, inspired by Frederick Taylor’s theories, revolutionizing the industrial production process: mass production was born.

His famous phrase:

“Any customer can have a car (Ford T) painted any colour that he wants so long as it is black”

Today, in the midst of the industry 4.0 era, Ford, we are certain, would no longer say that phrase. Rather, it might say:

“Any customer can have a tinted Ford in any color and type of paint they want, with the interior in the material of their choice, by ordering it directly from our website”.

This is not a vision. This is already a reality at major global companies, especially those in the fashion industry.

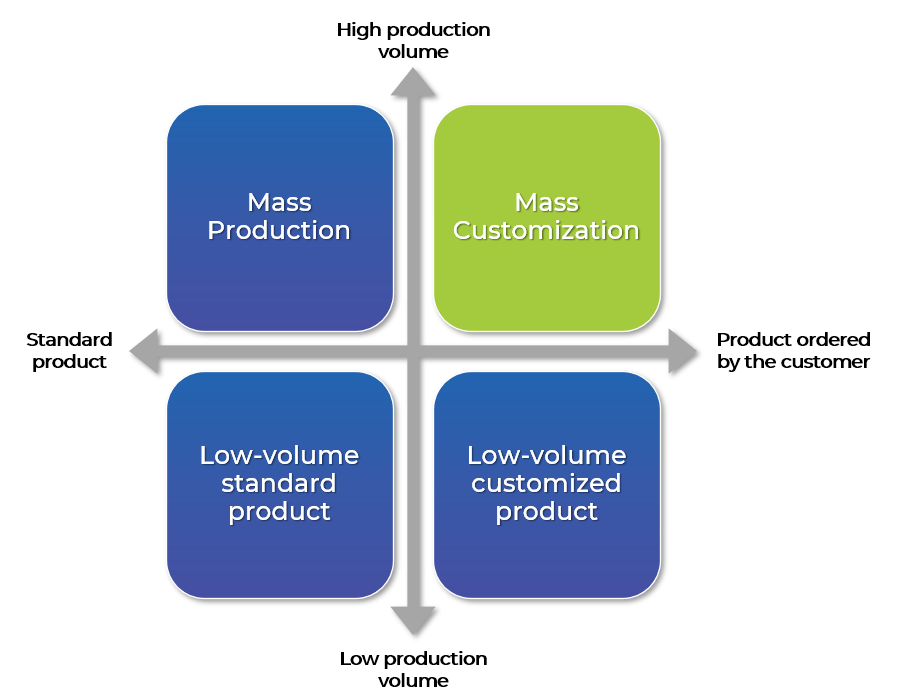

There’s no denying that digital transformation has played a key role in literally revolutionizing the manufacturing sector: mass production is evolving into mass customization.

The custom product has always existed … and has always covered a niche market exclusive, because positioned in a medium / high price range.

All this is changing and, slowly, you can customize anything, without finding a markup on what you order.

For some time now, many brands have allowed this type of customization, and we’re not just talking about e-commerce: some “physical” stores no longer host objects to sell, but to see and customize through special interfaces… and then go on to conclude the purchase through an “online” order.

The information acquired through dedicated platforms (terminals, websites, etc..) are taken and brought directly online.

Here, machines and operators are aware of everything they need to realize the object desired by the customer and its realization takes place without additional costs, neither for those who produce nor for the final user.

Obviously, in order to do this, you must be able to synchronize operational activities, monitor processes, and implement a production with a modular logic, and a complete interconnection between all processes.

All this can be easily defined with just two words: Smart Factory.

This new experiential flow has virtuous consequences on several levels:

- The ability to implement mass customization, differentiates the brand from direct competitors.

- It becomes a way to adapt marketing choices in a flexible way to market changes, which are increasingly frequent and fast.

- It constitutes a channel of continuous dialogue with customers, and allows you to provide immediate solutions to their expectations, building their loyalty over time.

- Value is continuously innovated

- A new market is born: using marketing terms, the red ocean is tinged a little more blue.

The role of Next

In this moment of evolution that truly represents a turning point, and excites the minds and creativity of many, Next is in it with its software services.

In the flow that goes from the order to the finished product, Next represents the bridge between the end user and the production lines: our “software agents” welcome the customer’s desires and bring them to the factory… and everything is born there.

This new frontier of digitalization in industry is changing consumer habits, industrial processes, but also the way we represent our work to ourselves.

In fact, we have always said that the customer is at the center.

Now we will have to change this vision by thinking that our customer’s customer is also at the center.

If you’re interested in the themes that we’re covering, follow and text us on Linkedin: we’d like to know YOUR opinion

You may want to use something even quicker, in that case, follow us on Telegram!

Recent Comments